It was on a quiet Sunday afternoon, my dog at my feet, reed mandrel in hand, when I received an interesting email in my inbox.

‘Hi Tanya, I’ve been endeavouring to improve the response of certain problem notes on my Contra Bassoon over the years, with many alterations already made and constant new discoveries being made. On the whole, the core of the instrument is excellent – but being a contra, I think there is always room to improve! I wonder whether the alterations explained below might be in your area of speciality?’

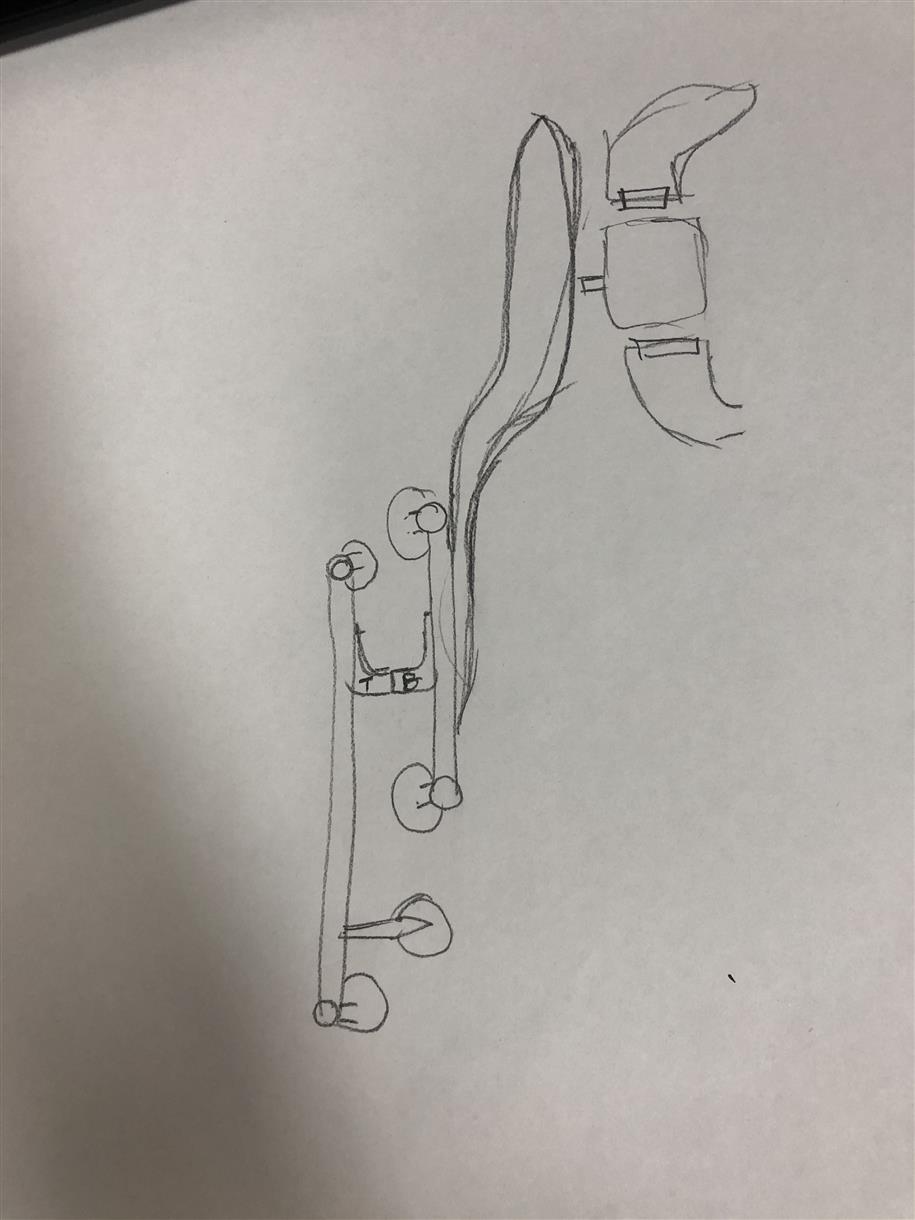

I was intrigued and excited at the prospect of being involved in such a project. It was a chance to create something not only beautiful but functional also. My client had included some wonderful concept images as well as a detailed description of the modifications. However, things are always far easier to explain in person, so we organised a meeting.

The request was as follows – create a touch piece to allow a pre-existing key to be used as a vent key on a Contra bassoon.

This seemed straight forward? But there were a few things that I needed to keep in mind with this new design.

1)With any modification like this, it is important to me to keep the function of the original key unchanged. The instrument works perfectly fine the way it was, as the manufacturer intended, all we were doing was improving it. If ever this Contra found a new owner I wanted my work to be able to be removed or disabled and not permanently affect the way the instrument was originally designed to function.

2) The new touch piece was going to be located in the right hand thumb cluster so there were a number of other keys that were intended to be used with it or needed to work the same around it. As if the thumb didn’t have enough keys to operate. I needed to take how it was going to be used into consideration.

3) The vent key in question was located on the tuning slide which had a 3cm north / south travel. Everything needed to function at any point within that plane of motion as well as allow the tuning to be removed completely for cleaning.

4) I wanted to be able to executed this job utilising the facilities, materials and tools available in my workshop.

After a nice chat with the client I kept the instrument in the shop for a couple of days so I could come up with a design. As I stared down at the impressive beast that evening, and scribbled on a few sheets of paper I actually had a real, lightbulb, moment. Honestly it was just like in the cartoons. The design was drawn (no Archibald prize for me I might add) and I got the clients blessing to get started.

With any job like this, how long something is going to take is anyones guess. No matter how much planning you do, there are always failures and surprises. This job was no different and it is not until you put your ideas into practice that any flaws in the designs are exposed.

My choice of solder was not always the right choice first time round. Too low a melting point and the connection did not withstand any manipulation. Too high a melting point and any of the surrounding connections could fall apart and I would have to start again. You would need to try and imagine how the parts looked three dimensionally, like a sculptor, which sometimes did not turn out the right way the first time. The main touch piece was re-made and re-designed several times before I found something that was going to clear all the key guards and keys when the tuning slide was moved up and down.

It can be a very mentally exhausting process but the one saving grace I had was how amazing my client was. The visits and feedback on prototypes was invaluable to creating the final product.

And so this is what I came up with. Does the job, ticks all the clients requirements and allows for future modifications if desired.

A huge thank you to all my colleagues and professionals who offered advice and help on the way. My hands feel like sandpaper and I would spend each night cleaning the metal shavings out from between my toes, but it is jobs like this that make me so glad I chose this career.